MK Products is proud that its welding technology is on its way to Mars.

Four years ago, the Jet Propulsion Laboratory in Pasadena, California obtained two complete orbital welding systems from MK Products for one of its latest and biggest projects, the Mars Science Laboratory (MSL) Program.

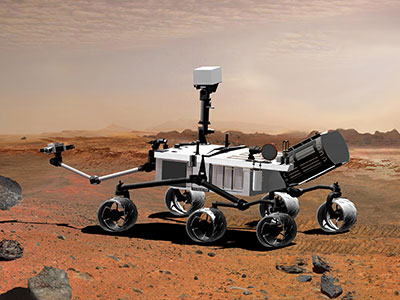

MSL’s Curiosity is a car sized rover equipped with cameras, environmental sensors, sample collecting tools, and lab quality geochemical instruments. It will use its diverse scientific payload to observe the environment, seek out interesting sites, and acquire dozens of samples of rock, soil, and atmosphere for onboard analysis, relaying its findings to scientists on Earth.

MK Products’ orbital line of welding equipment, along with its legendary push-pull wire feeding systems, has earned a well deserved reputation that is second to none among many welding professionals. MK Products has sold thousands of orbital power supplies and weldheads, as well as coolers, custom tooling and production tooling for these orbital systems.

Many of these orbital welding systems are being used around the world. China, Europe, India, Canada, and Central America are but a few of these international locations. More of these orbital systems are working here in the U.S., from smaller specialist shops to larger aerospace and defense companies.

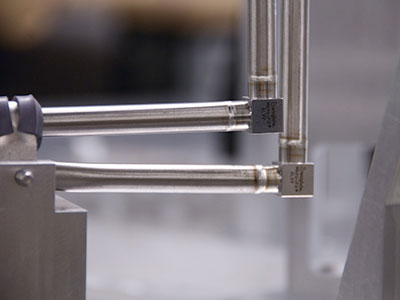

MK Product’s portable CobraTig 150 power supply, Cobra- Cooler, and Mini Micro 4000 weldheads were used to create 367 flight welds on the MSL Spacecraft, 155 welds were on the Rover-Loop and 212 were on the Cruise Loop, plus hundreds of practice and qualifying welds.

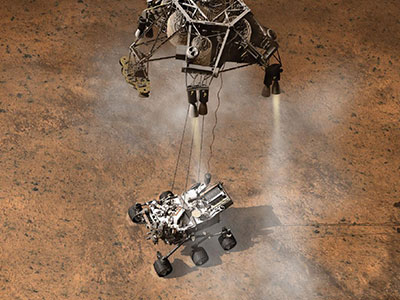

Mars Science Laboratory was launched on Nov. 26, 2011 and is scheduled to land on Mars on on Aug. 5, 2012 at 10:31 p.m. PDT (1:31 a.m. EDT, Aug. 6, 2012). It is in route to Gale crater, a site thought to have had conditions that are favorable to sustain life. MSL will reach its target by steering through the atmosphere, slowing its descent on a parachute, and using a rocket powered sky crane to place the deployed rover directly on Martian soil. Once on Mars, the rover is designed to explore many miles of terrain for at least two Earth years.

MK Product’s portable CobraTig 150 power supply, Cobra- Cooler, and Mini Micro 4000 weldheads were used to create 367 flight welds on the MSL Spacecraft, 155 welds were on the Rover-Loop and 212 were on the Cruise Loop, plus hundreds of practice and qualifying welds. All welds were X-rayed and systems were proof pressured and helium leak checked.

These orbital welding systems were set up in work cells, and since they are portable, they could also be moved to the spacecraft, as well, to perform orbital welds on actual flight hardware. These orbital welds were performed by JPL technicians to meet highly demanding specifications required for flight hardware.

The CobraTig 150 can also be easily converted to the manual TIG welding process, making this little brute of a power supply even more adaptable to many different welding applications.

For more information on MK Product’s state of the art orbital line of equipment, visit www.mkproducts.com. MK performs demonstrations of our equipment at our Irvine, California location, and will travel to your shop to provide demos and classes as well. If your application requires perfect welds, and you need equipment that can stand up to both high production demands and specialized applications, then trust MK Orbital to perform and deliver.